Expert Automation PLC Programming in Wisconsin

In today’s competitive manufacturing and processing landscape, precision and reliability are everything. With advanced automation technologies becoming more accessible, companies across the Midwest are seeking dependable ways to improve performance and reduce operational costs. For businesses ready to upgrade, Xtreme Automation LLC offers leading-edge automation PLC programming in Wisconsin—a critical service that connects hardware, software, and data to create seamless control solutions.

What is PLC Programming?

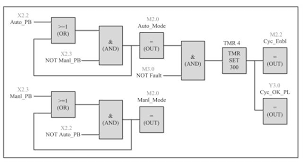

PLC stands for Programmable Logic Controller—a rugged industrial computer used to automate manufacturing processes. These controllers are designed to monitor inputs, make decisions based on programmed logic, and control outputs to drive machinery and systems.

PLC programming involves writing the logical instructions that tell machines exactly how to operate. Using software like RSLogix, TIA Portal, or GX Works, engineers program PLCs to automate:

Assembly lines

Batch mixing systems

Conveyors and sorters

Packaging machines

Pump stations

Robotic cells

Whether you’re in food processing, automotive, pharmaceuticals, or energy, reliable PLC programming ensures your systems operate with speed, accuracy, and minimal human intervention.

Why Wisconsin Businesses Need Professional PLC Programmers

Wisconsin’s manufacturing sector is one of the strongest in the nation. From dairy processing plants in Green Bay to paper mills in Wausau and advanced manufacturing in Milwaukee, the need for precise automation is growing fast.

A seasoned professional offering automation PLC programming in Wisconsin brings more than just code—they bring:

Deep understanding of electrical systems and control architecture

Experience with a range of PLC platforms (Allen-Bradley, Siemens, Mitsubishi, etc.)

Integration skills for SCADA, HMI, and sensor technology

Compliance knowledge for UL, NEC, OSHA, and local codes

By working with an experienced partner, companies avoid costly errors, reduce unplanned downtime, and build systems that scale easily.

Core Benefits of Expert PLC Programming

Investing in high-quality PLC programming provides long-lasting value. Here’s how:

1. System Reliability

Well-written programs are robust, easy to troubleshoot, and designed for continuous operation—even in harsh environments.

2. Improved Efficiency

Automated processes can perform repetitive tasks faster and more accurately than humans, increasing throughput and reducing waste.

3. Enhanced Safety

PLC programs incorporate safety interlocks, alarms, and emergency stop features, protecting both people and equipment.

4. Real-Time Control & Monitoring

Programs can be connected to HMI and SCADA systems, allowing operators to monitor performance and respond quickly to issues.

5. Scalability & Future-Proofing

Good code is modular and flexible, making it easier to add machines, change processes, or upgrade technology without full rewrites.

Key Features of Quality PLC Programming

When working with professionals for automation PLC programming in Wisconsin, you should expect:

Efficient Ladder Logic or Structured Text coding

Clear documentation for maintenance teams

Network-ready configuration for IIoT or MES integration

Seamless HMI interaction and error handling

Testing and simulation before implementation

These ensure that your automation systems remain consistent, dependable, and ready for long-term use.

Applications Across Industries

PLC programming is a vital part of automation in nearly every industrial sector in Wisconsin:

Food and Beverage: Accurate batching, pasteurization, and bottling controls

Automotive: Welding lines, quality inspection, and parts handling

Pharmaceuticals: Cleanroom processing, temperature control, and traceability

Water and Wastewater: Flow control, pump automation, and compliance reporting

Logistics and Packaging: Material sorting, packing, and conveyor automation

The Automation Process: From Planning to Production

Here’s how a typical PLC automation project unfolds:

Step 1: Needs Assessment

Your current systems are analyzed to determine automation goals and challenges.

Step 2: Design & Hardware Selection

A custom architecture is created, selecting suitable PLC brands and I/O configurations.

Step 3: PLC Programming

Software is developed and tested to ensure accurate logic, smooth transitions, and proper failsafes.

Step 4: Integration with HMI/SCADA

Interfaces are created for operator control and system-wide visibility.

Step 5: Installation & Commissioning

Engineers install the hardware, connect wiring, and fine-tune the system in real-time conditions.

Step 6: Training & Documentation

Operators are trained, and documentation is provided for troubleshooting and maintenance.

Step 7: Ongoing Support

Even after commissioning, regular updates and support keep your system optimized.

Signs You Need Automation PLC Programming

If you’re noticing any of the following in your facility, it’s time to consider automation:

Manual operations causing delays or inconsistencies

Frequent breakdowns or lack of process visibility

Inability to track performance or production metrics

Difficulty scaling operations or meeting safety regulations

Outdated or unsupported control systems

By upgrading with the help of an experienced team, your systems can achieve next-level performance and compliance.

Final Thoughts

Wisconsin’s industrial leaders understand that automation is not a luxury—it’s a necessity for sustainable growth and global competitiveness. With professional automation PLC programming in Wisconsin, you gain the control, reliability, and flexibility to streamline your processes and stay ahead of the curve.

For fully customized automation solutions, from design to deployment, Xtreme Automation LLC delivers the expertise and innovation to make your vision a reality. Their engineers bring deep industry knowledge and a passion for precision—ensuring your systems are built to perform today and evolve tomorrow.