Stainless Gratings for Durable and Corrosion-Resistant Industrial Solutions

In industrial settings, flooring, walkways, and drainage systems must do more than support heavy loads. They must also withstand harsh chemicals, moisture, and constant foot or vehicle traffic. Choosing the right material is vital for ensuring safety, longevity, and cost-effectiveness. Among the many options available, metal gratings stand out—but not all metals perform equally under strain. Stainless steel emerges as a leading choice where durability and corrosion resistance are non-negotiable.

What Are Metal Gratings?

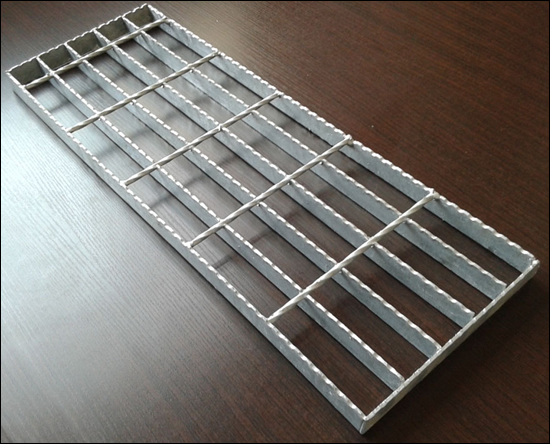

Metal gratings serve as flooring, stair treads, and covers in industrial and commercial environments. Typically made from steel bars arranged in a grid pattern, they may be welded, press-locked, or swaged. These platforms allow liquids, debris, and air to pass while providing a secure walking surface. The design addresses safety, hygiene, and structural requirements simultaneously.

Advantages of Stainless Gratings Over Other Materials

Choosing stainless steel elevates the utility and lifespan of gratings. Stainless steel resists corrosion, maintains its structural integrity, and offers excellent slip resistance—all while requiring minimal maintenance. Unlike carbon steel, it won’t rust in damp or chemical-prone environments. Compared with aluminum, stainless steel has higher load-bearing strength, which is essential for industrial uses. These benefits make Stainless Gratings an investment in safety, performance, and reduced replacement costs.

Corrosion Resistance in Harsh Environments

Chemical plants, wastewater treatment facilities, and offshore platforms pose extreme conditions, including exposure to acids, alkalis, and salt spray. Stainless steel contains chromium, which forms a passive oxide layer that protects against corrosion. Grades like 316 offer added molybdenum, enhancing resistance further in chloride-rich environments. This is why stainless gratings excel where ordinary materials fail.

High Strength and Load Capacity

Industrial operations often involve heavy equipment and constant foot traffic. Stainless steel gratings have high strength-to-weight ratios, ensuring durability without excessive mass. The grid design distributes loads efficiently, and various manufacturing methods control bar spacing and thickness to match specific structural demands. As a result, these gratings remain safe and reliable under extreme pressure.

Long Service Life with Minimal Maintenance

Over time, even the best materials deteriorate, impacting safety and costs. Stainless steel’s inherent resistance to rust, staining, and chemical attack ensures long service lifespans with minimal upkeep. A simple rinse or sweep keeps the surface clean. In contrast, carbon steel may require re-coating or replacement. The durability of stainless gratings reduces downtime and maintenance expenses, offering significant savings.

Enhanced Slip Resistance and Safety

Surface safety is critical in areas exposed to grease, water, or chemicals. Stainless steel gratings often include serrated or expanded profiles, improving traction and reducing slip risk. Open grid design also prevents water pooling, further enhancing safety. This makes these gratings ideal for stair treads, catwalks, platforms, and ramps in both indoor and outdoor environments.

Common Industrial Applications

Stainless steel gratings shine in various sectors:

Oil & Gas Platforms: They must endure saltwater, extreme weather, and heavy machinery.

Chemical Processing Plants: Resistance to strong chemicals and acids is essential.

Food & Beverage Facilities: Sanitation and hygiene standards require easy-to-clean, corrosion-proof flooring.

Wastewater Treatment Plants: They need durability under constant moisture and corrosive conditions.

Commercial Buildings: Staircases, drainage covers, and atriums benefit from functional, aesthetic, long-lasting flooring.

Design Options and Custom Fabrication

No two projects have the same specifications. Gratings come with varied bearing bar spacing, thicknesses, and edge types to match intended use. Options include:

Load capacities from pedestrian to vehicle-grade

Bar spacing for drainage, debris control, and light passage

Edges finished with flat bars, angles, or frames

Custom shapes for stair treads, trench covers, and vaults

Manufacturers can also finish gratings by polishing or passivating surfaces for hygiene or aesthetics. Custom fabrication ensures each installation fits precisely and performs optimally.

Economic Benefits Over Lifecycle

Although stainless gratings cost more upfront than carbon steel or aluminum, their performance justifies the investment. Long lifespans, minimal repairs, and reduced replacements deliver cost savings over time. In high-risk environments, safety benefits also outweigh initial costs. When factored over the lifecycle, stainless gratings offer superior return on investment.

Environmental and Sustainability Advantages

Today’s industries prioritize sustainability. Stainless steel fits well into eco-friendly practices, as it is fully recyclable without degradation. Using stainless gratings can contribute to green building certifications such as LEED. Additionally, longer service life reduces material turnover and waste, aligning with modern sustainability goals.

Choosing the Right Manufacturer

When sourcing stainless steel gratings, consider these factors:

Material Quality: Look for genuine 304 or 316 stainless steel with traceable certifications.

Manufacturing Standards: ISO, ASTM, and other industry certifications ensure quality control.

Customization and Support: Working with manufacturers capable of custom design is crucial.

Experience and Track Record: Case studies and references add confidence.

Delivery and Service: On-time delivery, installation support, and after-sales service matter greatly.

A reliable provider ensures installations are durable, safe, and compliant with regulatory standards.

Installation Best Practices

Even high-quality gratings perform poorly if installed incorrectly. For optimal results:

Elevated supports prevent corrosion from standing water

Thermal expansion gaps are necessary over long spans

Galvanic materials should be avoided in contact

Regular inspections catch structural or surface fatigue before it worsens

Following these steps preserves service life and safety.

Conclusion: Investing in Longevity and Performance

Stainless gratings balance the demands of durability, corrosion resistance, and operational safety. Through superior materials, structural strength, and minimal maintenance, they reduce long-term costs and improve performance. Their adaptability across industries makes them a go-to solution for critical infrastructure and specialized needs.

Selecting stainless steel gratings ensures installations that meet safety regulations while contributing to a sustainable future. As industries evolve, investing in quality materials becomes ever more essential. With proper planning, customization, and installation, stainless steel gratings deliver unmatched value and reliability—standing firm in industrial environments for decades to come.