The Essential Guide to Slurry Transfer Pumps: Powering Industrial Efficiency

In industries like mining, construction, wastewater treatment, and manufacturing, handling viscous, abrasive, or solid-laden fluids is a daily challenge. This is where slurry transfer pumps come in, offering robust solutions for transferring challenging mixtures of liquids and solids. Designed for durability and efficiency, these pumps are critical for maintaining smooth operations in demanding environments. In this article, we’ll explore what slurry transfer pumps are, their applications, key features, and why they’re indispensable for industrial processes.

For More Information: https://www.ic-machines.com/slurry-transfer-pump/

What is a Slurry Transfer Pump?

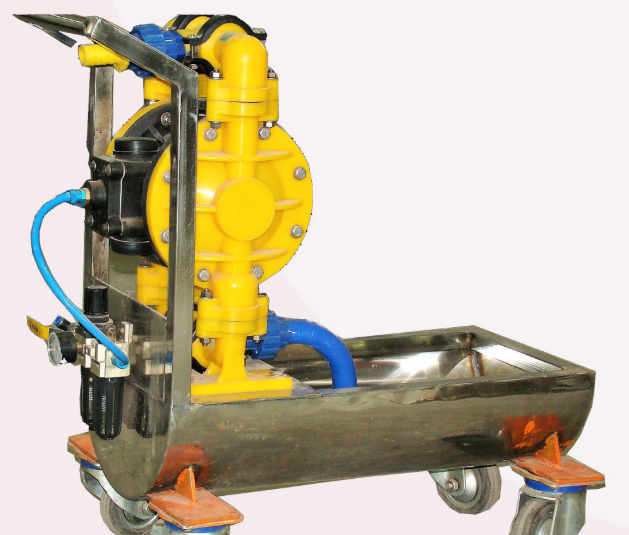

A slurry transfer pump is a specialized mechanical device engineered to move slurries—mixtures of liquids and suspended solids, such as mud, sand, minerals, or waste materials. Unlike standard water pumps, slurry pumps are built to withstand abrasive and corrosive materials, ensuring reliable performance in harsh conditions. They come in various configurations, including centrifugal, positive displacement, and submersible pumps, each tailored to specific industrial needs.For instance, the trolley-mounted slurry transfer pump from IC Machines is designed to transfer prepared slurries directly from primary or secondary mixers to storage tanks or in-cell dipping tanks, offering flexibility for different slurry compositions with intermittent washes.

Key Applications of Slurry Transfer Pumps

Slurry transfer pumps are versatile and serve a wide range of industries:

Mining: In mining operations, slurry pumps transport abrasive minerals, coal, and tailings. They handle high-tonnage slurries with large particles, ensuring efficient mineral extraction and waste management.

Construction: These pumps manage slurries containing sand, gravel, or cementitious solids, often used in concrete recycling or dewatering applications.

Wastewater Treatment: Slurry pumps move sludge and sewage with high solid content, preventing clogs and ensuring smooth processing.

Chemical and Pharmaceutical Industries: They handle corrosive or viscous liquids, maintaining sterile environments in pharmaceutical applications.

Dredging: Submersible slurry pumps, equipped with agitators, are ideal for dredging sand, silt, or gravel from rivers and waterways.

Features of High-Quality Slurry Transfer Pumps

When selecting a slurry transfer pump, certain features ensure optimal performance and longevity:

Robust Materials: Pumps are constructed from wear-resistant materials like high-chrome alloys, rubber linings, or elastomeric materials to combat abrasion and corrosion.

Non-Clog Design: Advanced designs, such as those with open impellers or agitators, prevent blockages by allowing large solids to pass through.

High Efficiency: Optimized hydraulic designs reduce energy consumption while maintaining high flow rates and pressure. For example, pumps from Sujal Engineering offer capacities up to 10,000 gpm and pressures up to 150 psi.

Versatility: Mobile or trolley-mounted pumps, like those from IC Machines, allow easy transport and adaptation to various slurry compositions.

Low Maintenance: Features like Cornell’s Cycloseal® technology eliminate the need for flush water, reducing maintenance costs in abrasive applications.

Types of Slurry Transfer Pumps

Slurry pumps come in several types, each suited to specific tasks:

Centrifugal Slurry Pumps: Ideal for high-volume transfer of low-viscosity slurries with suspended solids. They use impellers to create centrifugal force, moving fluids efficiently.

Positive Displacement Pumps: Best for thick, viscous slurries requiring precise flow control. These include lobe, diaphragm, and peristaltic pumps.

Submersible Slurry Pumps: Designed for underwater applications like dredging, these pumps are equipped with agitators to handle high-density solids.

Self-Priming Pumps: These pumps, like the EDDY Pump, mix and transfer slurries without clogging, ideal for high-solids applications.

Benefits of Using Slurry Transfer Pumps

Investing in a high-quality slurry transfer pump offers several advantages:

Durability: Built to handle abrasive and corrosive materials, these pumps have a long service life, reducing replacement costs.

Efficiency: High-performance designs minimize energy consumption and downtime, improving operational efficiency.

Versatility: Pumps can handle a wide range of slurries, from light mixtures to heavy, solid-laden fluids.

Cost Savings: Low-maintenance designs and non-clog features reduce operational and repair costs. For example, EDDY Pump’s self-priming units cut downtime compared to traditional centrifugal pumps.

Choosing the Right Slurry Transfer Pump

Selecting the right pump depends on several factors:

Fluid Characteristics: Consider the viscosity, solid content, and corrosiveness of the slurry.

Flow Rate and Pressure: Ensure the pump meets the required capacity and discharge pressure. For instance, Sujal Engineering’s pumps handle heads up to 240 ft.

Operating Conditions: Evaluate temperature, abrasiveness, and environmental factors to choose appropriate materials.

Application Needs: Determine whether a centrifugal, submersible, or positive displacement pump is best suited for the task.

Consulting with experts, such as those at IC Machines or North Ridge Pumps, can help tailor the pump selection to your specific requirements.

Why Choose IC Machines’ Slurry Transfer Pump?

IC Machines offers a trolley-mounted slurry transfer pump designed for seamless slurry handling. Its mobility allows it to transfer slurries of varying compositions to storage or dipping tanks, with intermittent washes ensuring clean operation. Built for durability and ease of use, this pump is an excellent choice for industries requiring reliable slurry transfer solutions.

For more information on slurry transfer pumps, visit IC Machines to explore their robust, trolley-mounted solutions.